Anti-static plastic bags are an excellent packaging material for printed circuit boards

Publication Time:

2023-02-18 09:29

Today, we will introduce several types frequently used in the electronics industry Anti-static plastic bags and their advantages. Let's take a look!

1) Shielding anti-static resealable bags

These are made of polyethylene and German-imported anti-static agents through special injection molding. They are easy to package and close with a pinch. This reduces complicated packaging procedures and is suitable for packaging electrical components, PCs, etc. Surface resistivity is 10^6-10^11Ω.

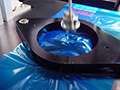

2) PE bright red anti-static plastic bag

This Anti-static plastic bags is an excellent packaging material for printed circuit boards, allowing for reliable release of static electricity generated by printed circuit boards and preventing damage.

3) Anti-static shielding bag

In order to enable plastics to shield electromagnetic waves, anti-static agents need to be applied to the plastics for coating treatment, which has a good shielding effect.

4) Anti-static bubble film

Anti-static bubble film and bubble wrap can prevent damage to products caused by impact or static electricity during manufacturing, transportation, and shipping. This bag is suitable for packaging static-sensitive electronic products.

5) Anti-static and moisture-proof bag

Suitable for the transportation and packaging of static-sensitive high-tech electronic products such as PCBs and ICs. It has anti-static and waterproof functions. The inner layer of the anti-static and moisture-proof bag is made of transparent anti-static material, and the inner layer is aluminum foil, with excellent high barrier and conductivity. Therefore, it has good anti-static, waterproof, and electromagnetic shielding properties, and its appearance is silver. It is mainly used for packaging electronic products that are sensitive to static electricity, and also require waterproof and anti-electromagnetic interference.

According to the processing technology, it can be divided into two categories:

First, it is made of sheet material, metal coating layer, and heat-permeable layer double-layer processing. It has the dual functions of "eliminating" static electricity itself and shielding external static electricity.

Second, PE anti-static plastic bags, mainly in the film blowing machine stage of production, add anti-static particles to the raw material particles to achieve the purpose of having an anti-static effect. It has the characteristics of simple manufacturing process and low production cost.

Based on these classifications, several common types are introduced below Anti-static plastic bags types.

Anti-static PE bag

Anti-static PE bags are made by blow molding a mixture of high-pressure polyethylene (LDPE) + linear high-pressure polyethylene (LLDPE) + anti-static masterbatch + color masterbatch + thickener, and then sealing and cutting. This product has all the characteristics of ordinary PE bags and anti-static function. Its raw material feels relatively soft, and the thickness can be adjusted freely. It is widely used in general electronic devices such as integrated circuits. As an outer packaging, it reduces costs and protects electronic devices from static electricity damage to electronic components due to friction between insulators.

The characteristics of this type of packaging bag are low price, and the main disadvantage is that the anti-static value cannot be too high, especially in the dry season in the north, suitable for products with insufficient anti-static requirements.

Previous

Related News

VCI rust preventive paper - A new type of rust preventive packaging material

VCI rust preventive paper is a new type of rust preventive packaging material made by coating rust preventive base paper with volatile corrosion inhibitor (VCI).

How to use and precautions for anti-rust film bags

Rust preventive film bags are a new type of packaging material widely used in the packaging industry. They are specifically designed to prevent corrosion, oxidation, and contamination of industrial metal products during storage. The following is a detailed introduction to rust preventive film bags:

Detailed introduction to VCI rust preventive paper

VCI rust preventive paper (Volatile Corrosion Inhibitor Paper) is a special packaging material that protects metals from corrosion by releasing volatile rust preventive molecules (VCI). The following is a detailed introduction to VCI rust preventive paper:

High-end packaging solutions: A crucial element in building brand image

High-end packaging solutions, especially anti-rust film bags, are key to shaping brand image. Exquisite packaging not only protects product quality but also enhances consumer brand recognition. Let's explore this field together and discover the unlimited possibilities of high-end packaging!

Easy to Use: Packaging Techniques with PE Stretch Film

This article provides a detailed guide on using PE stretch film for packaging, making it easy for you to get started. Whether it's moving, storage, or transportation, mastering these tips will make packaging so simple!

Environmental Characteristics and Sustainable Packaging Solutions of PE Stretch Film

This article explores the eco-friendly characteristics of PE stretch film and how sustainable packaging solutions can promote its application. Through recycling, the use of bio-based materials, and the research and development of degradable products, we can work together to contribute to the protection of our planet.

Follow on Mobile

Address: No. 88, Lizhu Highway, Qianma Village, Liyang City, Changzhou City, Jiangsu Province (Changzhou Wanhe Technology Co., Ltd.)

Email:jszuomeibzkj@yeah.net

Tel:133 8286 2588

copyright © 2025 Jiangsu Zuo Mei Packaging Technology Co., Ltd.