How to use anti-static plastic bags

Publication Time:

2023-02-08 09:46

Anti-static plastic bag It is widely used in the electronics, optoelectronics, and high-precision electronic components industries, especially in the microelectronics industry where anti-static sensitivity is crucial. However, according to the requirements of electronic products, customized anti-static bags also have stricter regulations on quality, halogen bulbs, processing technology, and production processes.

Generally, the packaging bags used by most people are made of insulating materials. However, packaging bags for sensitive components are made of anti-static materials, generally called anti-static plastic bags, also known as anti-static shielding bags, dark gray transparent electrostatic bags, and anti-static moisture-proof bags.

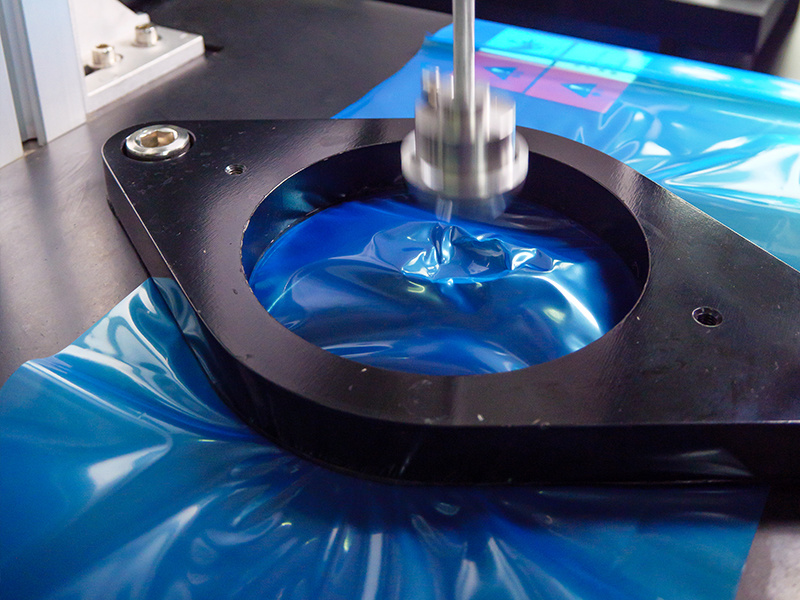

PE anti-static bags can achieve their anti-static function in two ways.

1. Adding anti-static agents internally. A fatal flaw of this method is that the surface resistivity is too high, reaching 10E10-10E12, resulting in a weak anti-static effect.

2. Applying anti-static agents externally to achieve the anti-static effect. This externally applied anti-static agent is called an external anti-static agent. Both methods can be combined to ensure a more reliable anti-static effect for PE anti-static bags.

Anti-static plastic bags are made by mixing and injection molding high-pressure polyethylene (LDPE) + linear high-pressure polyethylene (LLDPE) + anti-static masterbatch + color masterbatch + thickener, and then sealing and cutting to form.

This product has all the characteristics of ordinary PE bags and anti-static function. Its raw material feels relatively soft, and the thickness can be adjusted freely. It is widely used in integrated circuits and other general electronic devices. As an outer packaging, it reduces costs and protects electronic devices from electrostatic damage to electronic components caused by friction between insulators. This anti-static bag is an ideal packaging material for printed circuit boards, allowing the electrostatic charge generated by the printed circuit board to be released, preventing damage.

The thickness of PE anti-static packaging bags can be adjusted freely, and the specifications are unlimited. Different sizes and styles of packaging bags can be customized, such as flat bags, three-dimensional bags, bellows bags, self-adhesive, self-sealing, etc., and the color can also be customized according to customer requirements. PE anti-static bags are mainly used for packaging electronic components, printed circuit boards, PC boards, motherboards, communication products, etc.

Anti-static plastic bag Mainly used for:

1. Household use: packaging various foods such as vegetables, fruits, fish, meat, and seasonings, suitable for refrigeration and freezing.

2. Packaging various dried fruits, tea, beans, sugar, and medicines, suitable for waterproof purposes.

3. Packaging clothes, shoes, various ornaments, metal parts, and various paper products.

SGS certified, suitable for packaging electronic components, printed circuit boards, PC boards, motherboards, communication products, etc.

Can be used as packaging for new products exported to Europe, America, and Japan. This bag is sturdy and suitable for high-end product packaging, commonly used for packaging high-end export products.

Related News

VCI rust preventive paper - A new type of rust preventive packaging material

VCI rust preventive paper is a new type of rust preventive packaging material made by coating rust preventive base paper with volatile corrosion inhibitor (VCI).

How to use and precautions for anti-rust film bags

Rust preventive film bags are a new type of packaging material widely used in the packaging industry. They are specifically designed to prevent corrosion, oxidation, and contamination of industrial metal products during storage. The following is a detailed introduction to rust preventive film bags:

Detailed introduction to VCI rust preventive paper

VCI rust preventive paper (Volatile Corrosion Inhibitor Paper) is a special packaging material that protects metals from corrosion by releasing volatile rust preventive molecules (VCI). The following is a detailed introduction to VCI rust preventive paper:

High-end packaging solutions: A crucial element in building brand image

High-end packaging solutions, especially anti-rust film bags, are key to shaping brand image. Exquisite packaging not only protects product quality but also enhances consumer brand recognition. Let's explore this field together and discover the unlimited possibilities of high-end packaging!

Easy to Use: Packaging Techniques with PE Stretch Film

This article provides a detailed guide on using PE stretch film for packaging, making it easy for you to get started. Whether it's moving, storage, or transportation, mastering these tips will make packaging so simple!

Environmental Characteristics and Sustainable Packaging Solutions of PE Stretch Film

This article explores the eco-friendly characteristics of PE stretch film and how sustainable packaging solutions can promote its application. Through recycling, the use of bio-based materials, and the research and development of degradable products, we can work together to contribute to the protection of our planet.

Follow on Mobile

Address: No. 88, Lizhu Highway, Qianma Village, Liyang City, Changzhou City, Jiangsu Province (Changzhou Wanhe Technology Co., Ltd.)

Email:jszuomeibzkj@yeah.net

Tel:133 8286 2588

copyright © 2025 Jiangsu Zuo Mei Packaging Technology Co., Ltd.